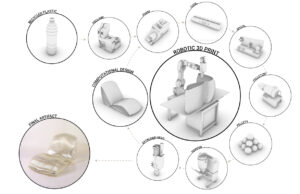

The Co-designing Circular Plastics project was a small initiative. As proof of concept, PI 3D printed a scaled chair (1:2) with an industrial robotic arm.

Development of a Co-designed Circular Interface

A user interface (UI) was developed to integrate distinct aspects of user-friendly and circular economy.

Implementation of Co-designed Circular Construction

A design-for-fabrication method was developed to integrate material properties and robotic fabrication into consideration. This integrated design method follows the principles of co-designing circular plastics. The process includes the preparation of recycled materials for printing a chair with an industrial robotic arm.

The Result of Co-designed Circular Plastics

A scaled model (1:2) of a chair was designed based on human ergonomics while considering material and fabrication capacities.

Since 2018, PI has developed an advanced technology curriculum that highlights the agency of materials in our built environment. Courses like ARCH5500-Computational design and construction, ARCH5500–Behavioral robotic fabrication, ARCH 5500-Cognitive design and fabrication, and ARCH5500-Robotic additive manufacturing focus on applying advanced technologies in design. This fund supported these ongoing curricula to advance UVA’s position in sustainability for design and construction. It helped students learn a new economic model in design and construction.

Project Funding

This project was funded by the Jefferson Trust.

Related Projects

This project was further developed through additional funding from the Jefferson Trust in Chair No. 7.

Author and Image Credit

Ehsan Baharlou

Image Credit

Ehsan Baharlou, CT .lab, University of Virginia, 2023