Courses, News

Robotic Ecotectonics

Description

Climate change is challenging humanity. There is an increasing need to develop sustainable building systems for zero or negative carbon emissions. Innovation in ecologically sound materials and sustainable construction techniques could revolutionize the building industry, which in turn could enable the rapid construction of building envelopes using local and low-carbon materials. Robotic additive manufacturing’s versatility can be used to construct complex adaptive envelopes that actively support local ecosystems.

This course challenges traditional linear construction methods by introducing a circular economy approach. The “reduce-reuse-recycle” strategy promises a way to decrease embodied carbon emissions in building sectors. The research will explore the possibility of developing ecological tectonic (ecotectonic) constructions. Ecotectonic construction, which considers multispecies design, moves beyond anthropocentric tectonics. It combines upcycling waste materials with robotic 3D printing to reduce the negative impacts of building envelopes.

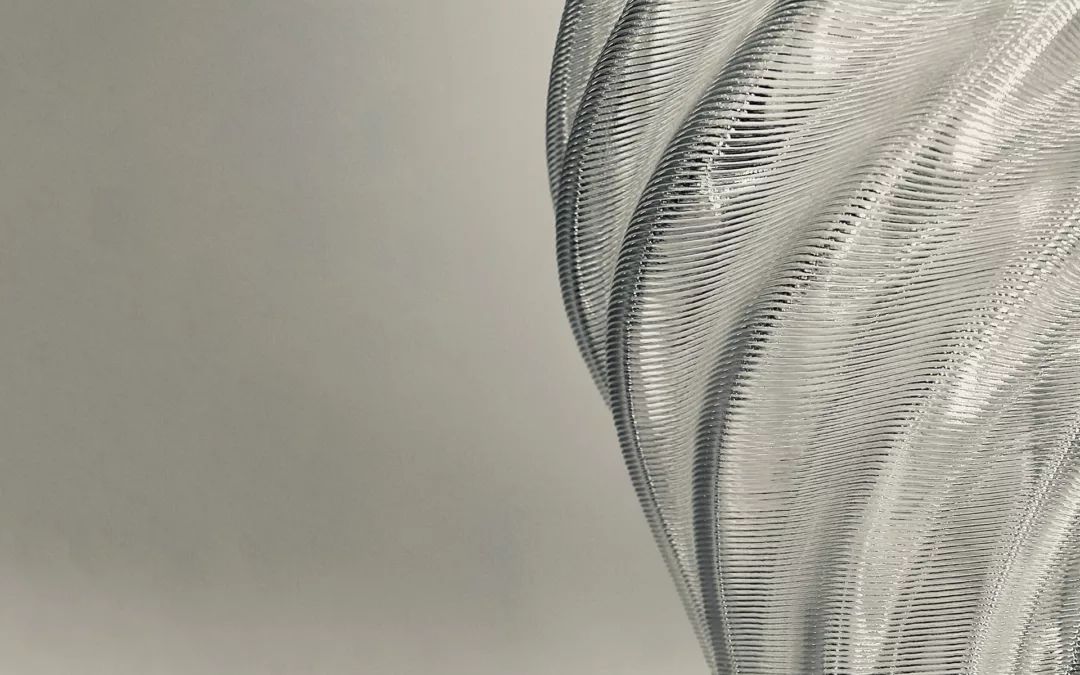

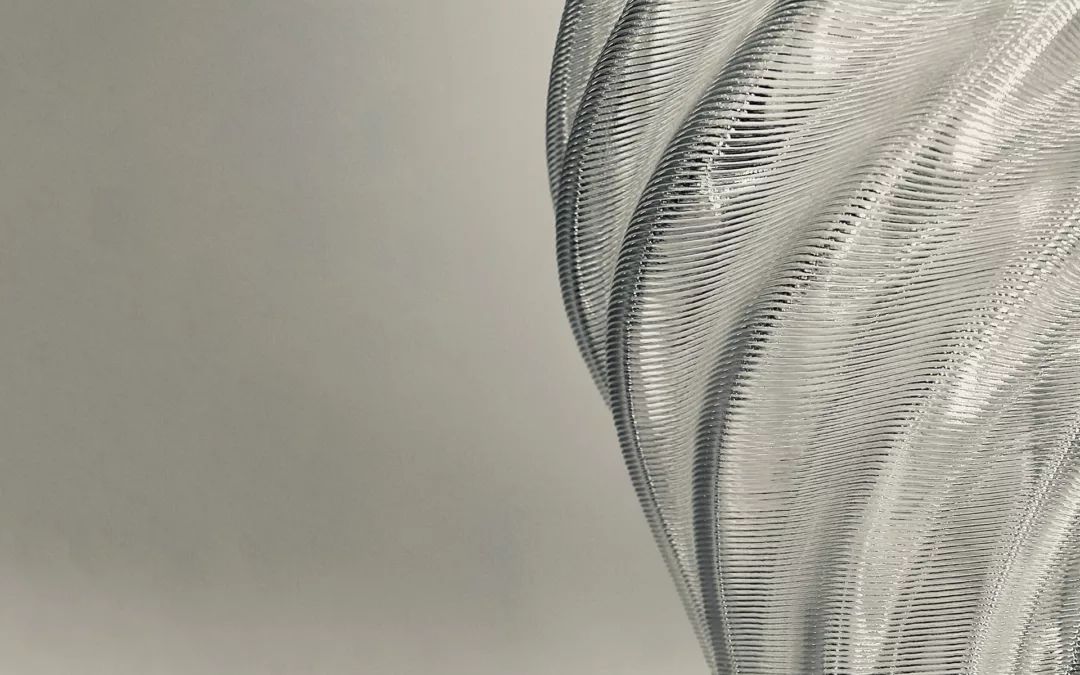

Students will design and construct eco-composite envelopes, which may include features to capture carbon, block heat radiation, or serve as an acoustic system. To promote sustainable construction, this studio will apply innovative methods to reuse recyclable plastic waste or repurpose local soil mixed with agricultural by-products. Repurposing these unconventional materials requires analyzing their characteristics and the use of additives to make them suitable for 3D printing. Robotic additive construction enables the addition of layers based on performance needs. Different layers—like green cover, insulation, and structural layers—can be 3D printed together to foster a proper ecology to maintain the structure as a living organism.

Students will explore the design-to-fabrication process by developing prototypes to evaluate each phase through an ecologically active material system, computational design, and robotic additive construction. Students will produce detailed drawings of a façade or envelope system, conceptual drawings of the implementation of this system on a building scale, and a 3D printed full-scale mock-up of the ecological envelope system.

Image Credit

E. Baharlou, University of Virginia, 2021.

Courses, News

Additive Tectonics

“When a structural concept has found its implementation through construction, the visual result will affect us through certain expressive qualities which clearly have something to do with the play of forces and corresponding arrangement of parts in the building, yet cannot be described in terms of construction and structure alone. For these qualities, which are expressive of a relation of form to force, the term tectonic should be reserved.”

— Eduard F. Sekler (1960), “Structure, Construction, Tectonics”, in Structure in Art and in Science.

Description

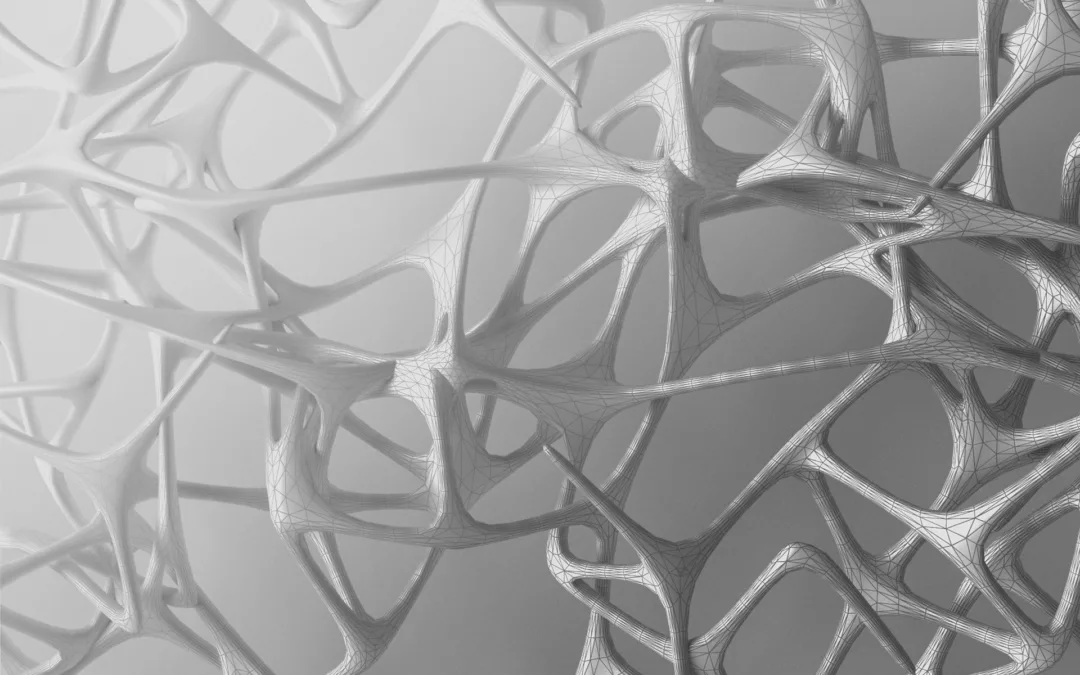

Advances in computational design methods and fabrication techniques provide new possibilities for architectural designers to consider different paradigms for design and making. These paradigms emphasize the relationship between formation and materialization. Through robotic additive manufacturing, designers can construct buildings or building elements quickly.

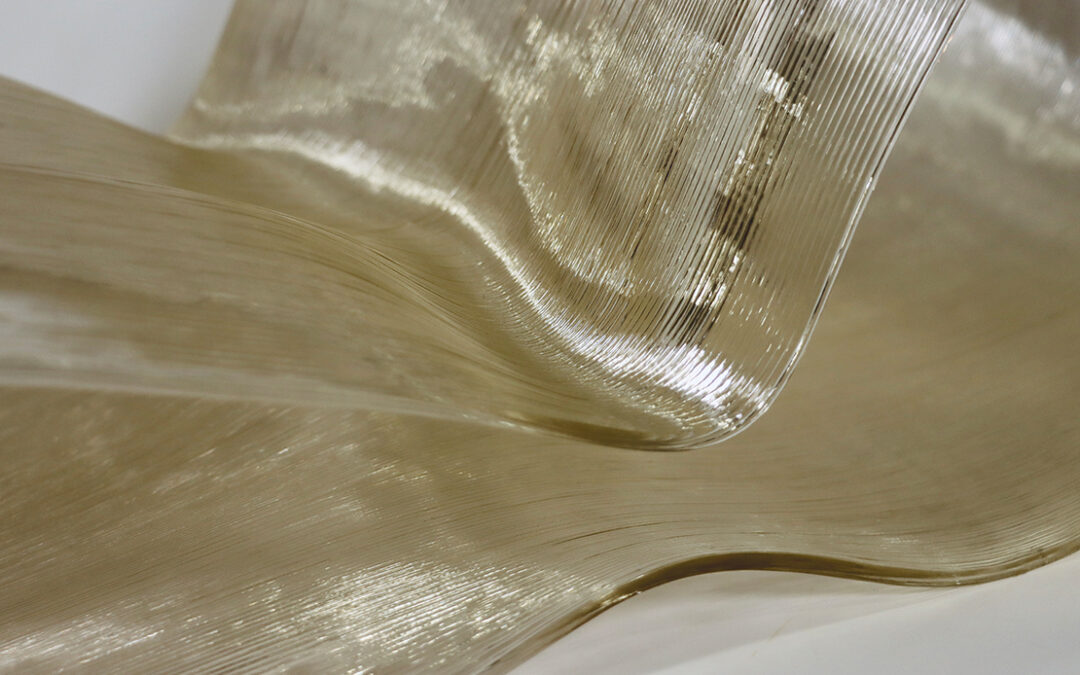

The studio “Additive Tectonics” explored the tectonic expression of additive manufacturing in different architectural contexts, from constructing affordable housing with earth materials to investigating the construction of settlements on other planets. The studio focused on the exploration of such architectural tectonics as an abstracted skin or wall system; a tower or a column as a structural element; a vault or a shell as a roof system; a hut or a shed; or other, new building tectonics. One-to-one structures were designed for the North Terrace at the University of Virginia’s Campbell Hall.

Students explored additive tectonics through three stages. The material system development stage demonstrated various materials—such as bio-based, bio-degradable, or bioplastic materials—and their properties and limitations in additive manufacturing. In computational design development, students considered the material properties and fabrication constraints in prototyping. Finally, robotic additive construction—which can be defined as abstraction, formation, rationalization, and materialization to explore novel tectonics—enabled students to execute their design prototype to examine their design’s tectonic potential in building an architectural element.

A series of integrative workshops supported this studio. Formation workshops introduced Grasshopper as a CAD software that can be used for form generation. Materialization workshops presented students with a numerical-based fabrication process. Students learned to control an industrial robotic arm and 3D-print tectonic prototypes.

Image Credit

E. Baharlou, University of Virginia, 2021.

![[non-standard] Mass Timber Architecture](https://ct.lab.virginia.edu/media/2023/09/2020_CT_KH_JM_DT_TN-1080x675.webp)