![[non-standard] Mass Timber Architecture](https://ct.lab.virginia.edu/media/2023/09/2020_CT_KH_JM_DT_TN-1080x675.webp)

[non-standard] Mass Timber Architecture

[non-standard] Mass Timber Architecture

“Technology is the answer, but what was the question?”

— Cedric Price, 1966.

Description

This studio focused on ecological construction to explore the potential of mass timber technologies to address new and growing climate change threats. It introduced students to applying the process of design to the construction of mass timber systems. Using mixed-reality technologies, students developed a co-design framework to shift from material- and fabrication-centered design processes to human-centered design-making. They were directly involved in the entire process, from design to construction. The aim of this research studio was to develop [augmented] robotic fabrication to construct experimental mass timber structures at the school of architecture.

This studio aimed to introduce students to mass timber design in architecture. It included four phases: 1) wood science, 2) wood processing, 3) wood construction, and 4) mass timber system design. In wood science, students learned wood anatomy and related physical and mechanical properties of wood, such as hygroscopic and anisotropic behaviors. In wood processing, students were introduced to wood manufacturing of mass timber systems such as cross laminated timber (CLT), glues laminated timber (glulam), and nailed laminated timber (NLT). Through a series of case studies, students explored wood processing such as lamination and connections to generate spatial wood tectonics.

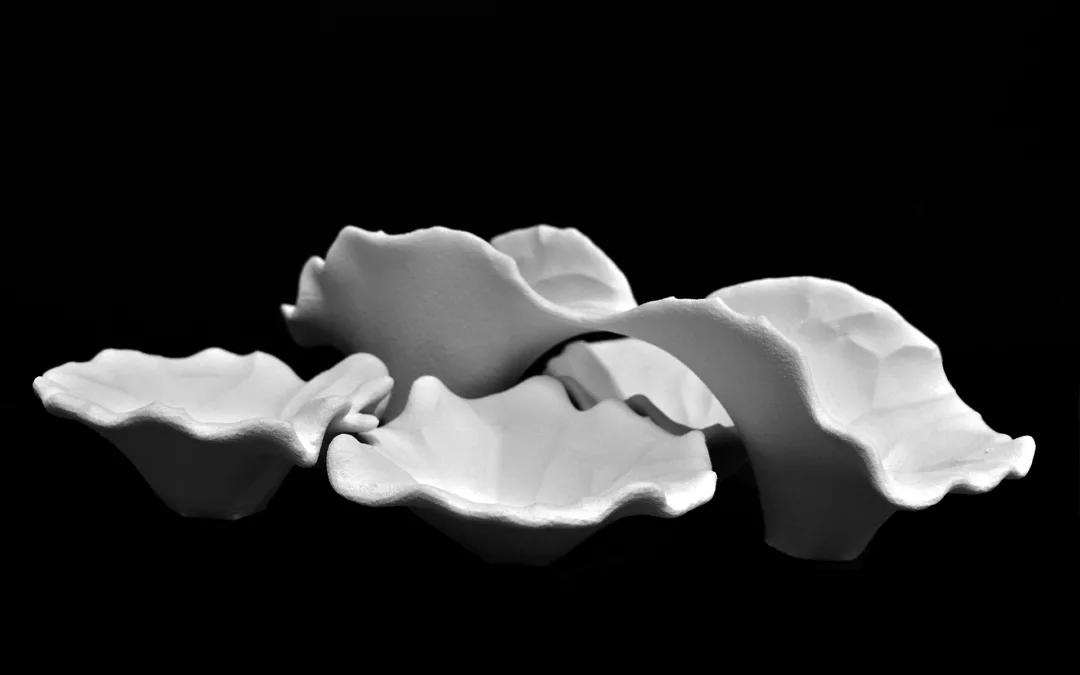

In wood construction, students examined different construction techniques such as CNC milling and robotic fabrication to prototype small-scale timber systems. In the final phase of this studio, students designed a building element. The envisioned elements were 1) an abstracted skin or wall system, 2) a tower or a column as a structural element, 3) a vault or a shell as a roof system, 4) a hut or a shed, or other invented building elements. This one-to-one timber structure was designed for Campbell Hall’s North Terrace at UVA.

Students also explored design space as a parametric space through a parameter-based framework. The computational framework geometrically differentiated and parameterized timber wood structures. This framework integrated the fabrication constraints and material characteristics as generative drivers. Students learned advanced robotic controls to understand the role of fabrication agency in timber construction. They applied additive and subtractive robotic fabrication to develop a tectonic connection between timber elements. Students collaborated in fabrication and assembly processes through mixed-reality (MR) technologies to apply their design intention in real-time. Students applied these three methods to prototype scaled models which enabled them to understand the augmented process of design-to-construction of a one-to-one demonstrator.

Selected Project

Generative Crossed Timber System | Developed by: Chris MacDonnell, Ziwei Shen, Yuwen Zhou

Image Credit

K. Huntsinger, J. Magenheimer, D. Trepp, 2020.