Selected Project

Robotic Serpentine Wall

Description

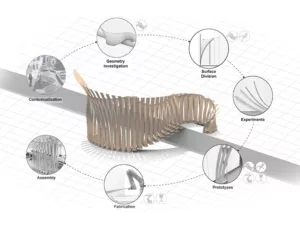

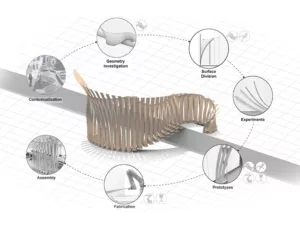

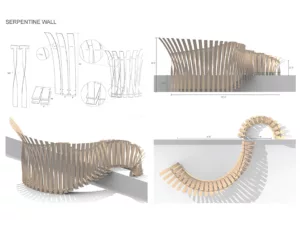

The project “Robotic Serpentine Wall” investigates new, unexpected uses of wood to construct an inhabitable structure. It created a structure that 1) celebrates steam bending’s ability to radically change wood’s structural potential; 2) is inhabitable, improves the site on which it was built, and is connected with the history of its larger context; and 3) was data- and mathematically driven.

Program Development

© L. Kirssin, B. Penny, T. Rhodes, (Photographer: Kwadwo Tenkorang), 2020.

© L. Kirssin, B. Penny, T. Rhodes, 2020.

© L. Kirssin, B. Penny, T. Rhodes, 2020.

© L. Kirssin, B. Penny, T. Rhodes, 2020.

© L. Kirssin, B. Penny, T. Rhodes, (Photographer: Kwadwo Tenkorang), 2020.

© L. Kirssin, B. Penny, T. Rhodes, (Photographer: Kwadwo Tenkorang), 2020.

© L. Kirssin, B. Penny, T. Rhodes, (Photographer: Kwadwo Tenkorang), 2020.

© L. Kirssin, B. Penny, T. Rhodes, 2020.

© L. Kirssin, B. Penny, T. Rhodes, 2020.

© L. Kirssin, B. Penny, T. Rhodes, (Photographer: Kwadwo Tenkorang), 2020.

© L. Kirssin, B. Penny, T. Rhodes, (Photographer: Kwadwo Tenkorang), 2020.

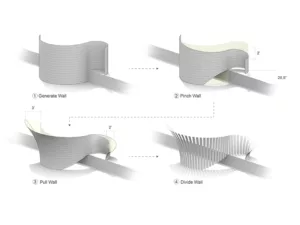

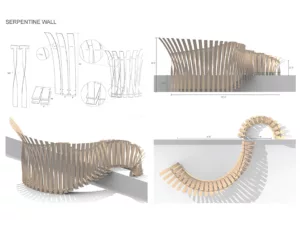

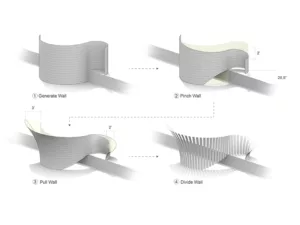

This project responded to its site—the North Terrace of UVA’s School of Architecture—in two ways. First, it negotiated the step between the ground and the top of the planter box, a distance of 26 ½”, in a way that encourages small group interactions. Second, the form responds to the complex history of serpentine walls at UVA. This sinusoidal shape was manipulated to create a structure that produced a small gathering area on one side and a seat on the other. It was then reverse-engineered to minimize the number of unique components upon construction.

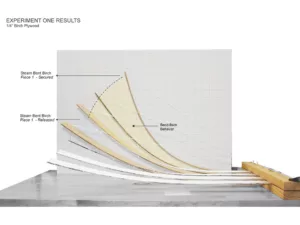

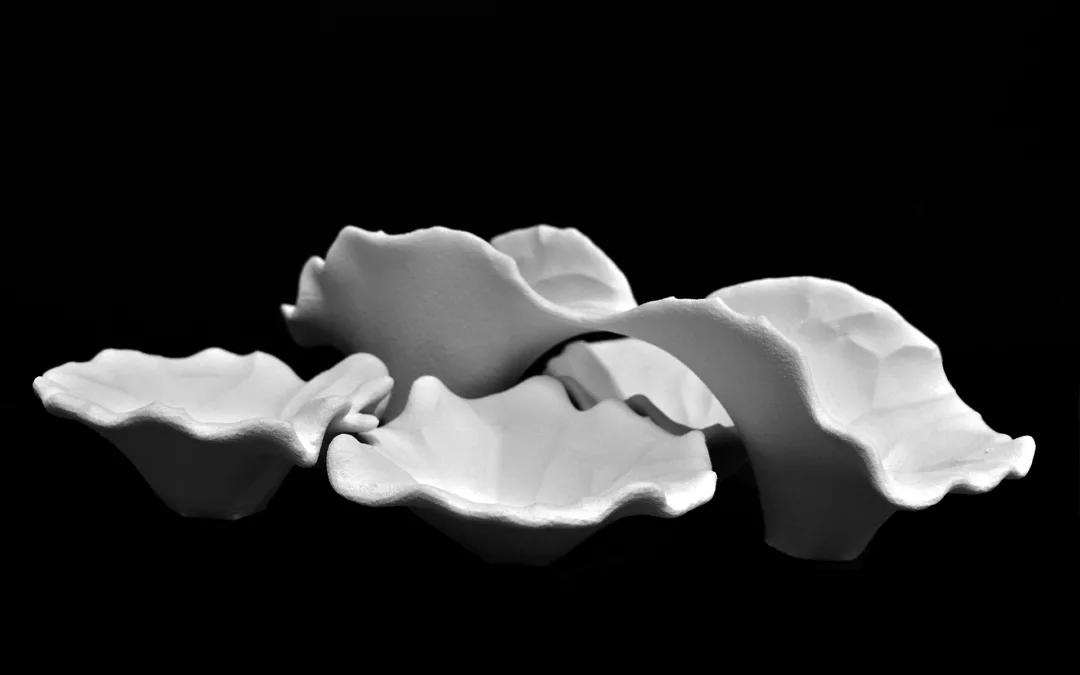

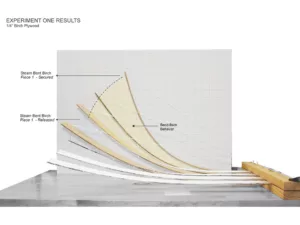

Several experiments were conducted to test the amount that pieces of birch plywood and oak plywood reverted to their original shape following steaming and either bending or twisting; birch plywood performed better in both. A third experiment determined plywood pieces needed to be a minimum length of 24” to prevent cracking as a result of twisting.

Prototyping the structure led to the discovery that the primary pieces work in tension, not compression. This in turn resulted in the inclusion of additional support pieces for greater structural stability.

The final design was constructed through a complex process of cutting, twisting and bending, and slotting the pieces together. Each piece was machine cut according to the specific measurements dictated by the digital design. They were then steamed before being twisted and bent into position, allowed to dry, and put together. The final assembly process revealed that the connections between wall sections were necessary for the structure to be free-standing.

This project was awarded the 2021 Bruce Abbey Technology Award. It was featured on the University of Virginia School of Architecture’s website.

Author and Image Credit

Leah Kirssin, Bay Penny, Trenton Rhodes.

Instructor

Ehsan Baharlou

Courses, News

Introduction to Cognitive Design and Fabrication

“The manifest form—that which appears—is the result of a computational interaction between internal rules and external (morphogenetic) pressures that, themselves, originate in other adjacent forms (ecology). The (pre-concrete) internal rules comprise, in their activity, an embedded form, what is today clearly understood and described by the term algorithm.”

— Who is afraid of formalism?, Sanford Kwinter.

Description

Advances in design computation methods and fabrication techniques provide new possibilities for designers to consider different paradigms for design and making. These paradigms emphasize the relationship between formation and materialization. Form manifestation can be investigated through behavioral, emotional, and cognitive approaches. Cognitive and emotional design approaches center humanity in production processes to address their needs. The implication of human-centered design methods will change the production of goods from mass-production and mass-customization to more personalized manufacturing. This new form of industrial thinking challenges disciplines such as architectural design to profoundly investigate innovative design approaches and fabrication techniques.

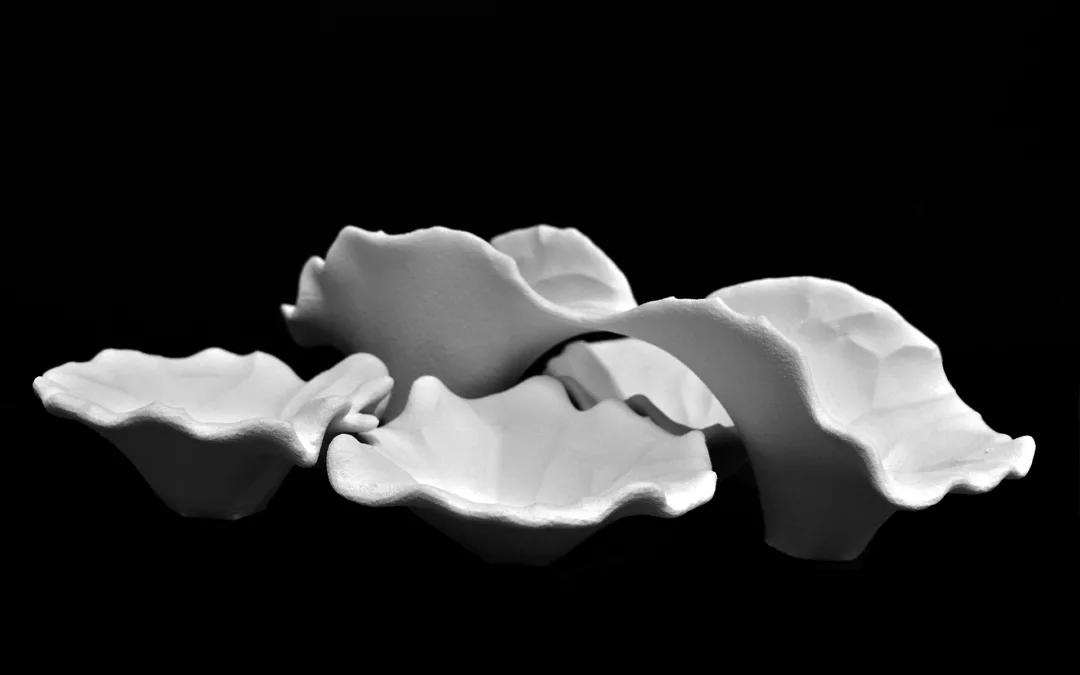

The elective course “Introduction to Cognitive Design and Fabrication” introduced students to cognitive design principles, computational design processes, and additive manufacturing techniques. After learning the principles of cognitive design, students developed their own design that applied these principles to the design of “Everyday Things”. This included, for example, items essential to responding to COVID-19, such as face masks, safety glasses, and face shields. In addition, students were introduced to additive manufacturing techniques such as 3D-printing and robotic additive manufacturing to materialize their design.

This course included two workshops. The first, on computational design, discussed integrative computational tools, such as Autodesk Fusion 360, to sketch, design, simulate, and manufacture a design concept. The second workshop focused on robotic 3D-printing and introduced advanced robotic controls to explore experimental robotic fabrication in design.

Selected Project

SMASK: A Smart Mask for Amid/Post-COVID | Developed by: Meng Huang and Xun Liu

Image Credit

L. Aldinger, C. Arias, S. Katz, ICD, University of Stuttgart, 2015/16.

Courses, News

Behavioral Robotic Fabrication

“A system is “soft” when it is flexible, adaptable, and evolving, when it is complex and maintained by a dense network of active information or feedback loops, or, put in a more general way, when a system is able to sustain a certain quotient of sensitive, quasi-random flow.”

— Soft systems, Sanford Kwinter.

Description

Advances in design computation methods and fabrication processes provide new possibilities for designers to explore the manifestation of form in terms of materialization. Form manifestation can be investigated through behavioral approaches that are associated with basic material characteristics and fabrication parameters. Behavior-based approaches expand the design solution space, which previously was unavailable for designers restricted to top-down processes. Behavioral fabrication is a bottom-up process of integrating fabrication constraints and capacities into design processes.

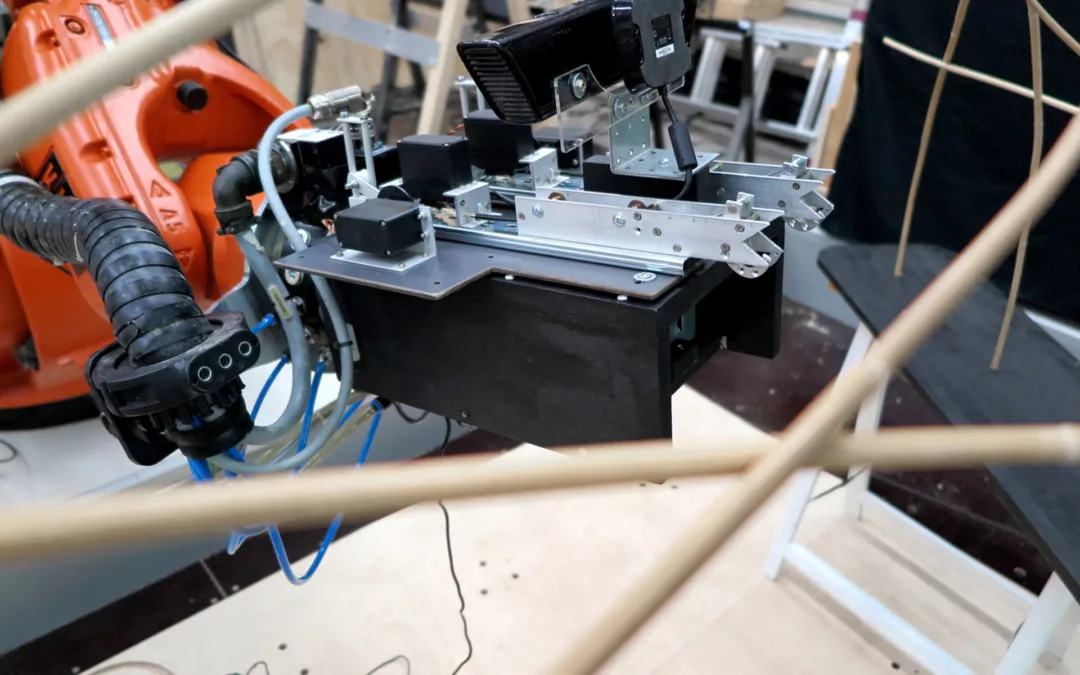

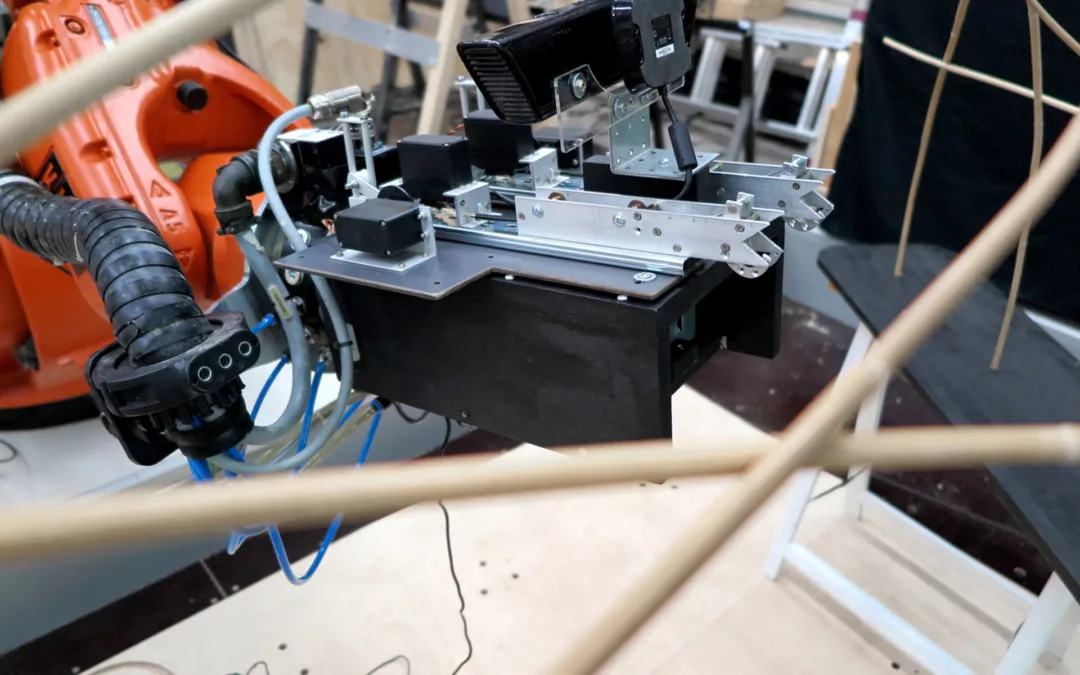

The elective course “Behavioral Robotic Fabrication” introduced students to behavioral fabrication in architectural design. Students learned basic robotic fabrication processes that have been applied in architectural design thus far. Students were introduced to advanced robotic controls for digital fabrication and explored experimental robotic fabrication processes in art and architectural design. Accordingly, students gained practical experience in robotic fabrication by working with an industrial-scale robot, KUKA KR AGILUS.

This course focused on behavioral aspects of robotic fabrication processes, such as on-line, responsive, or interactive robotic controls. Students investigated different types of robotic fabrication tools (end-effectors) to build a custom end effector. Through sensory systems, students developed a soft system to adapt the physical realm of fabrication to the digital design environment.

Image Credit

G. Brugnaro, ICD, University of Stuttgart, 2015.

Courses, News

Introduction to Computational Design and Construction

“The manifest form—that which appears—is the result of a computational interaction between internal rules and external (morphogenetic) pressures that, themselves, originate in other adjacent forms (ecology). The (pre-concrete) internal rules comprise, in their activity, an embedded form, what is today clearly understood and described by the term algorithm.”

— Who is afraid of formalism?, Sanford Kwinter.

Description

The elective course “Introduction to Computational Design and Construction” was complementary to the advanced research studio “Wood Proto-architecture I”, offered the same year. Advances in computational design and fabrication techniques provide new possibilities for designers to explore the manifestation and materialization of form. This course introduced students to these methods in design and construction. These approaches allow architects to consider material and fabrication characteristics in the early stages of the design process.

This course provided students with basic knowledge of developing computational design techniques in architecture that can be seamlessly integrated into design and fabrication processes. This introduction enhanced students’ knowledge in computational design by developing associative and algorithmic design strategies. Students investigated relatively simple mathematical and physical principles to generate complex geometries in the context of proto-architecture. This generative approach provided an algorithmic understanding of developing physical materialization.

Concurrently, the course focused on digital fabrication processes that integrate computational manufacturing techniques’ limitations and possibilities into design processes. Students learned robotic fabrication and advanced robotic control for digital fabrication. Accordingly, students gained hands-on experience working with the industrial-scale robot, KUKA KR AGILUS. Thus, students were introduced to a fabrication-driven method that provides a new approach in the design of complex geometric forms.

Image Credit

J. Höll and G. Kazlachev, ICD, University of Stuttgart, 2013/14.